Welding Cables for Industrial and Commercial Welding Applications

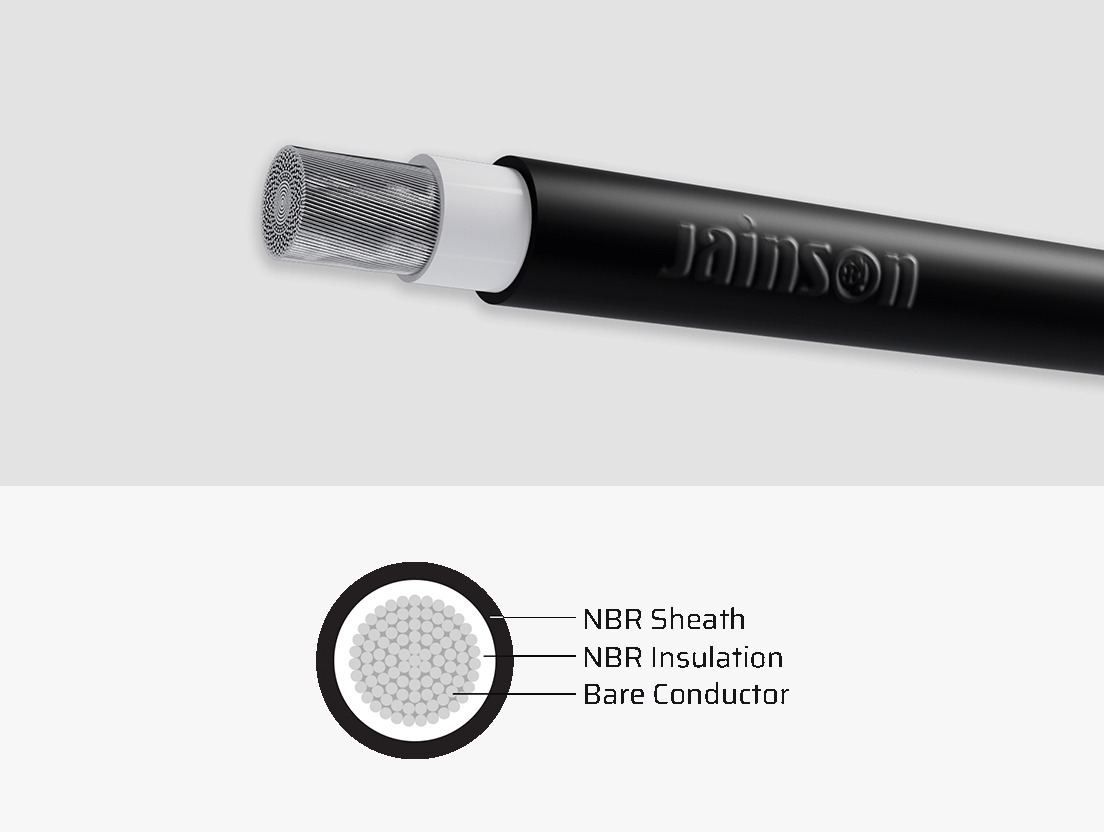

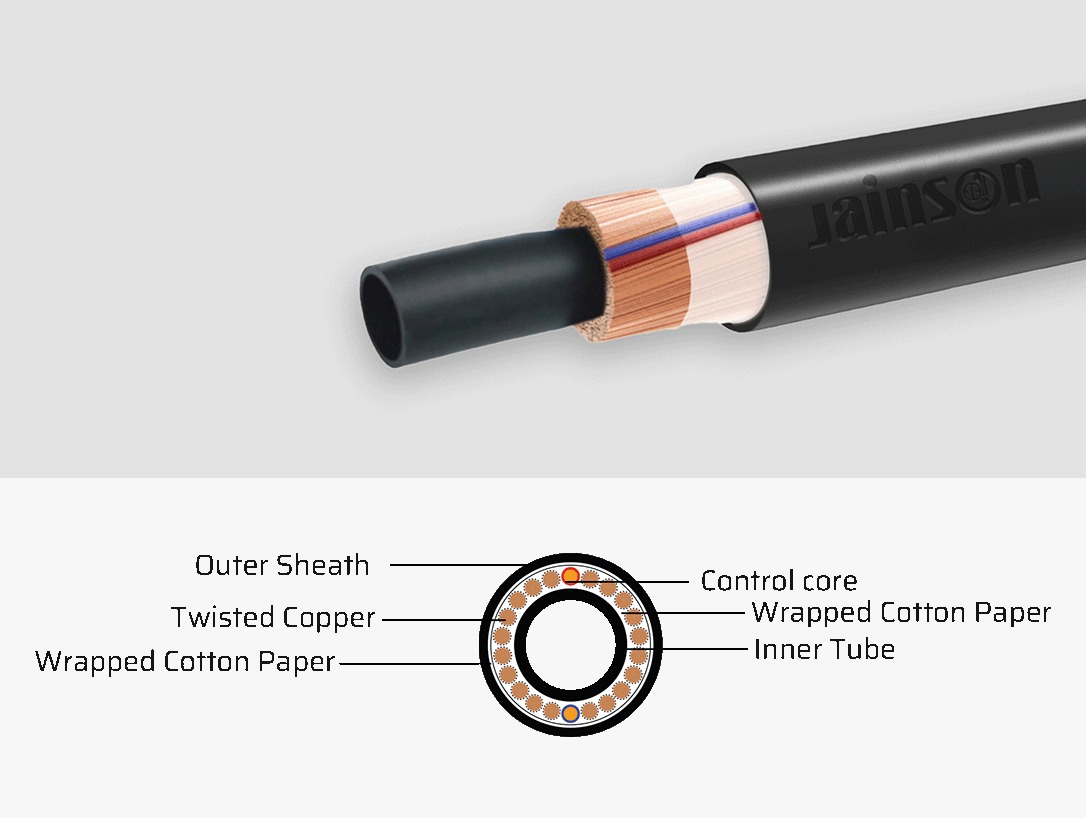

Welding cables are designed to provide a safe and stable electrical connection between the welding machine and the electrode. These cables carry high current, withstand extreme heat generated during welding and maintain consistent conductivity in industrial environments. Jainson welding cables are engineered using fine-stranded copper conductors and high-quality rubber insulation so they deliver consistent current flow, superior flexibility and long-term durability. These cables are built to tolerate repeated bending, abrasion and mechanical stress — making them ideal for fabrication workshops, repair units, shipyards and construction sites where cables are moved, dragged or flexed frequently.

Key features

- High flexibility for constant movement and handling

- Pure fine-stranded copper conductor for low resistance and stable current transfer

- Heat-resistant rubber insulation suitable for welding applications

- Abrasion, oil and chemical resistant outer jacket (NBR / EPDM options)

- Stable performance across a wide temperature range

- Compatible with standard welding machines (MMA, MIG, TIG)

- Available in multiple cross-sections and sizes for different current needs

- Long operational life with minimal hardening or cracking

Technical specification table

| Parameter | Details |

|---|---|

| Conductor | Pure fine-stranded copper |

| Insulation | Rubber based (NBR or EPDM depending on variant) |

| Jacket | NBR / EPDM |

| Temperature range | –20 °C to +85 °C (continuous, model dependent) |

| Voltage rating | 450 V – 750 V |

| Current carrying capacity | Varies by cable cross-section (16 mm² – 95 mm²) |

| Flexibility class | Class 5 or Class 6 conductors |

| Abrasion resistance | High |

| Oil / chemical resistance | Yes |

| Color options | Black (custom colors on request) |

| Standards | IS, IEC or equivalent standards |

- Manual metal arc (MMA) welding

- MIG and TIG welding operations

- Industrial fabrication and manufacturing

- Automotive workshops and repair shops

- Shipbuilding and offshore projects

- Construction and infrastructure projects

- Heavy equipment maintenance and repair

Jainson focuses on conductor purity, high strand counts and premium insulation materials. The result is durable, flexible cables that maintain conductivity under mechanical stress and heat — reducing downtime and increasing safety in industrial welding operations.

FAQs

Welding cables use a very high strand count copper conductor and flexible rubber insulation, enabling them to handle high current, repeated movement and heat. Regular power cables have fewer strands and less-flexible insulation.

Yes. Jainson welding cables offer weather, moisture and UV resistance (depending on variant). Use EPDM or special outdoor jackets for extended outdoor exposure.

Typical continuous operation range is −20 °C to +85 °C; confirm on the product datasheet for specific variant.

They are compatible with most standard welding machines (MMA, MIG and TIG). Select cable cross-section based on machine current requirements.

Choose cable size by the required current (ampacity) and length. For light use 16–25 mm² may suffice; for heavy industrial welding choose 50–95 mm². If unsure, share machine specifications and distance; we’ll recommend sizes.