A high-performance welding cable featuring ultra-flexible, fine-stranded copper conductors with robust double NBR rubber insulation, designed for demanding welding environments. Its superior flexibility and flame-retardant properties ensure reliable performance under constant movement, rugged conditions, and thermal stress. With excellent resistance to abrasion, oil, chemicals, ozone and weathering this cable is ideal for industrial and workshop welding applications.

| Cross Sectional Area | Copper Construction | Inner Dia | Outer Dia Appx. | Max. Conductor Resistance at 20˚C | Current Rating | Non Welding Application | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Welding Application | ||||||||||

| Duty Cycle | ||||||||||

| 100% | 85% | 60% | 30% | 20% | ||||||

| Sq. mm. | Nos. / Dia. mm | mm | mm | Ω/km | amp | amp | amp | amp | amp | amp |

| 10 | 322 / 0.20 | 6.30 | 9.90 | 1.910 | 105 | 115 | 135 | 190 | 235 | 110 |

| 16 | 511 / 0.20 | 8.00 | 10.70 | 1.210 | 135 | 145 | 175 | 245 | 302 | 138 |

| 25 | 798 / 0.20 | 9.50 | 12.10 | 0.780 | 180 | 195 | 230 | 330 | 402 | 187 |

| 35 | 1121 / 0.20 | 11.00 | 14.20 | 0.554 | 225 | 245 | 290 | 410 | 503 | 233 |

| 50 | 1596 / 0.20 | 12.30 | 16.30 | 0.386 | 285 | 310 | 370 | 520 | 637 | 295 |

| 70 | 2220 / 0.20 | 14.40 | 18.70 | 0.272 | 355 | 385 | 460 | 650 | 794 | 372 |

| 95 | 1349 / 0.30 | 16.60 | 20.80 | 0.206 | 430 | 470 | 560 | 790 | 961 | 449 |

| 120 | 608 / 0.50 | 18.20 | 23.00 | 0.161 | 500 | 540 | 650 | 910 | 1118 | 523 |

| 150 | 760 / 0.50 | 21.10 | 27.60 | 0.129 | 580 | 620 | 740 | 1040 | 1297 | 608 |

| 185 | 943 / 0.50 | 23.80 | 30.80 | 0.106 | 660 | 715 | 850 | 1200 | 1476 | 690 |

| 240 | 1225 / 0.50 | 26.80 | 34.00 | 0.0801 | 710 | 770 | 916 | 1296 | 1587 | 744 |

| 300 | 1498 / 0.50 | 30.30 | 37.50 | 0.0641 | 800 | 850 | 1035 | 1450 | 1790 | 840 |

| 400 | 2035 / 0.50 | 33.60 | 41.30 | 0.0486 | 925 | 1000 | 1195 | 1690 | 2070 | 970 |

The number of wires is approximate and wire diameter is nominal; they shall be such as to satisfy the requirements of conductor resistance of IEC 60228 / DIN VDE 0295 / IS 8130 / BS 6360

In view of continuous improvements in our design and process, specifications given here in are subject change without notice.

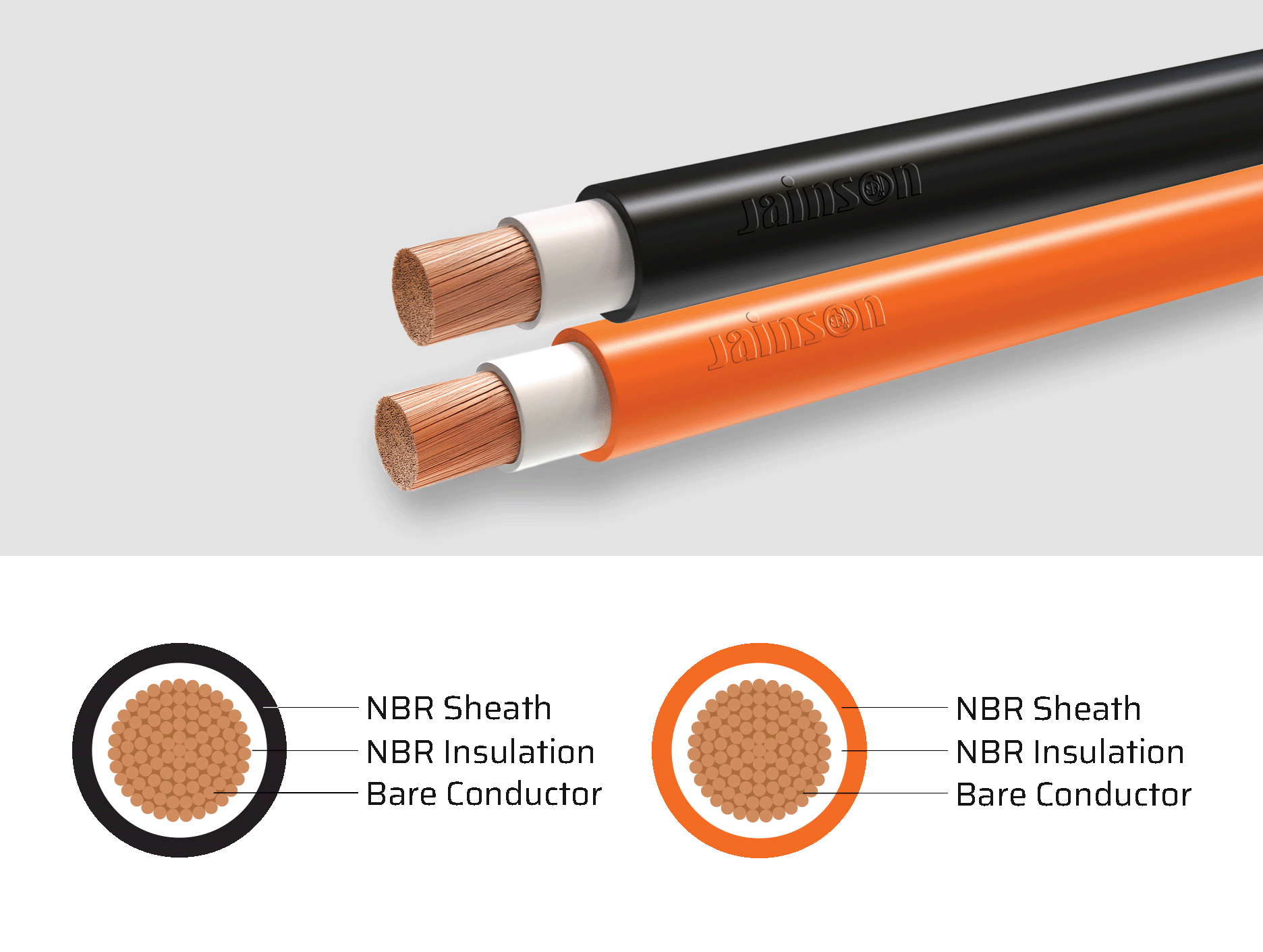

> All are flexible conductor

> Insulation material is NBR

> Sheath material is NBR

| Ambient temperature °C | 20° | 25° | 30° | 35° | 40° | 45° | 50° | 55° | 60° | 65° |

| Rating Factor | 1.04 | 1.00 | 0.96 | 0.91 | 0.87 | 0.82 | 0.76 | 0.69 | 0.64 | 0.57 |